The Pyrochemical Research Laboratory (PRL) is an open access national user facility, established to provide academic, public, and private sector organisations with access to state of the art equipment to support world leading research in molten salt pyrochemical processing.

The laboratory consists of a suite of interconnected controlled atmosphere dry-boxes. These are equipped with the necessary furnaces, cell systems, potentiostats and other equipment for characterisation, required for research into, and development of, each of the essential elements of pyrochemical reprocessing at the laboratory scale.

There is flexibility in the configuration of the PRL, with users able to request individual modules to demonstrate the feasibility of individual components of pyrochemical reprocessing. Alternatively the entire facility may be utilised to demonstrate a complete pyrochemical process, including monitoring and analysis.

Access to the PRL facility is facilitated by the lab manager (Dr Justin Elliott) who can provide advice and guidance on utilising facility equipment to meet your research needs.

Aims of the PRL

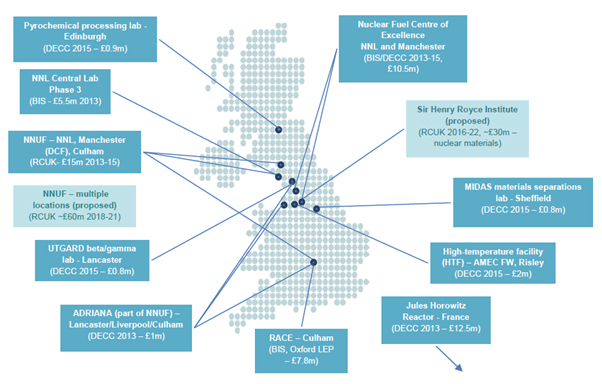

The University of Edinburgh established the PRL facility, in partnership with the Department of Energy and Climate Change (DECC) and is affiliated with the National Nuclear User Facility (NNUF). The PRL facility is unique in providing the facilities to develop and demonstrate integrated pyrochemical reprocessing of nuclear fuel, using fuel relevant non-radioactive compositional mixtures at laboratory scale, along with the required process monitoring.

The PRL facility is therefore a unique research capability, providing hands on user access to state of the art equipment and instrumentation, utilising medium scale inventories, enabling the UK to deliver internationally competitive R&D.

The PRL facility provides the equipment and infrastructure required to achieve the key medium term objective of the proposed NIRAB spent fuel recycle programme in pyroprocessing. Namely, this is to demonstrate each of the essential components of a fast reactor fuel pyroprocessing recycle technology within 5 years, leading to hot cell testing in 10 years.