The PRL facility has four interconnected but individually bookable glove boxes, each tailored to a given stage of a pyroprocessing system with associated equipment.

Capabilities and Equipment

Box 1 – Salt preparation

Salt and chemicals storage

High Accuracy Scales

Vacuum Oven (250 C)

Large granite mortar and pestle

Mortar grinder

Box 2 – Large and medium scale salt measurement

Large well furnace

Stirrer Arm

Bench top tube furnace

Potentiostat and high current module, including laptop with control software

Box 3 – Medium scale salt measurement

Bench top tube furnace x2

Potentiostat and high current module, including laptop with control software

Box 4 – Salt analysis and optical/spectro-electrochemical measurements

ONH analyser

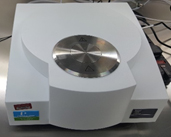

TGA/DSC

Imaging bay

Water cooled tube furnace with optical windows

IR - Raman - UV vis source and detectors

External to glove box

Tower tube furnace x2

Schleck line for gas and vacuum lines

Salt loop designed for in-suite flowing salt measurement

Microscope to 1000x magnification